Zero-waste

technology approach

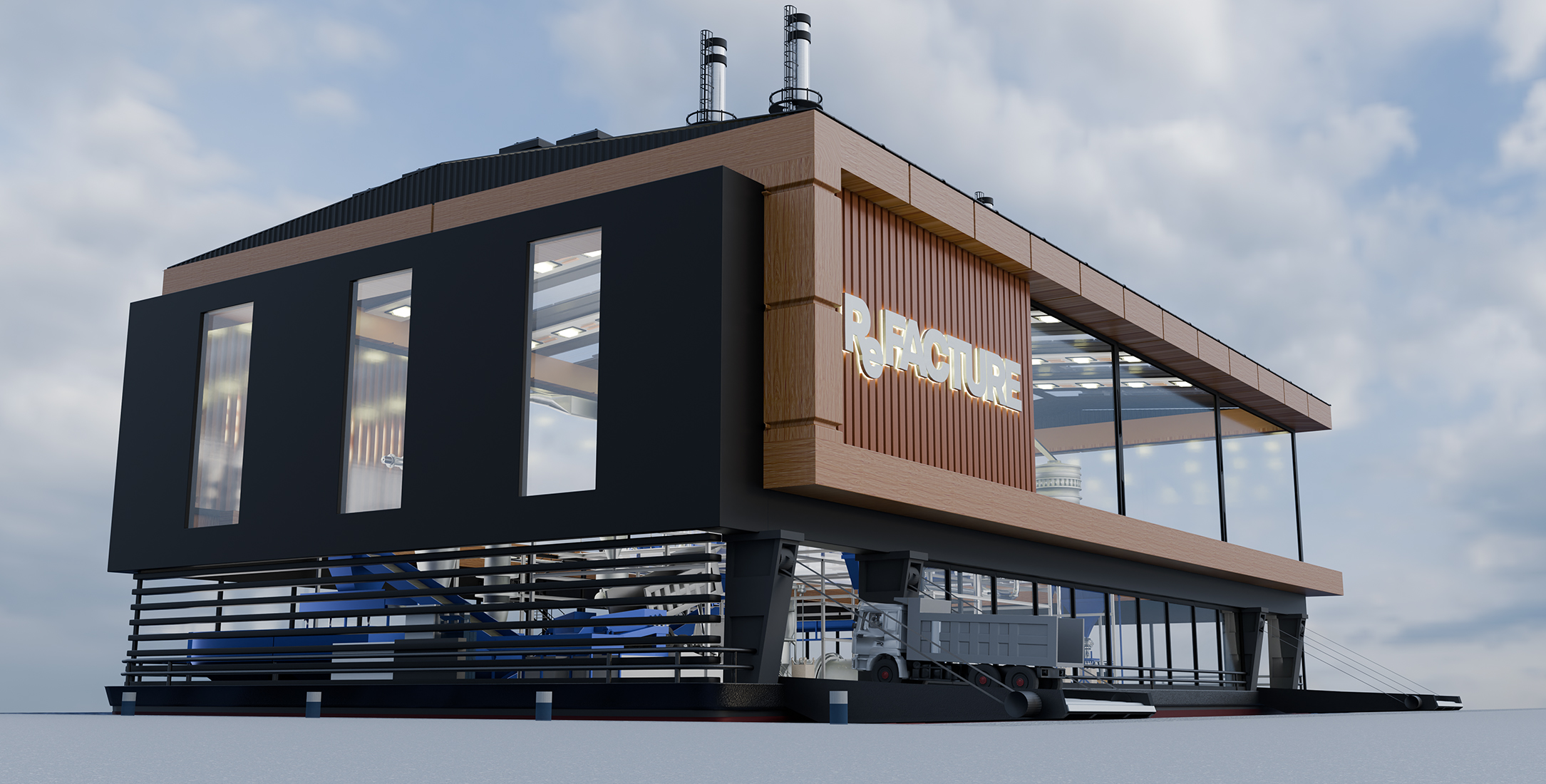

Refacture is a holistic waste management system utilizing the highest and best use technologies for recovering resources from problematic waste streams.

Assembling commercially proven technologies

under one roof.

- 1 – Feedstock Engineering

- 2 – Real-Time AI Chemical Intelligence

- 3 – HTP (High-temperature Plasma)

- 4 – Advanced Refining & Separation

- 5 – Manufacturing & Circular Supply

1 – Feedstock Engineering

Material recovery & pre-treatment

Refacture begins by analyzing and conditioning industrial byproducts — such as spent pot lining, black mass, and metallurgical residues — using precision material recovery and classification systems. This ensures that each feedstock stream enters the plasma process optimized for maximum yield, purity, and energy efficiency.

Sorting

Sorting and separating for Anaerobic Digestion;

Separation

Separating remaining organic materials; and,

Recovery

Recovering non-contaminated inorganics.

2 – Real-Time AI Chemical Intelligence

Our facilities integrate continuous, live chemical analysis and AI-driven process control to monitor and refine plasma reactions in real time. This digital backbone allows for adaptive temperature, gas, and power modulation, resulting in consistently high-purity material recovery and process stability across complex waste streams.

- Conveyance of materials through chemical analysis system;

- Molecular sorting; and,

- Temporary storage before blending for HTP advance manufacturing.

3 – HTP (High-temperature Plasma)

At the heart of Refacture’s process is our proprietary High-Temperature Plasma (HTP) system. Unlike conventional incineration or smelting, HTP reaches extreme, controlled temperatures in inert atmospheres, converting industrial waste into valuable advanced materials such as silicon carbide, scandium, and rare earth compounds—with near-zero emissions.

4 – Advanced Refining & Separation

Recovered materials move through tailored chemical and physical separation systems—halogenation, condensation, leaching, and selective extraction—to isolate critical elements at high purity. These materials form the basis for advanced ceramics, semiconductors, and strategic alloys.

5 – Manufacturing & Circular Supply

Refacture’s integrated production model brings material recovery and advanced manufacturing under one roof. By producing critical materials directly from industrial waste, we help industries close their resource loop—reducing emissions, supply-chain risk, and dependence on imported raw materials.